CORYNEX®

Secretion production of peptides/proteins by gram-positive bacterium

CORYNEX®

Secretion production of peptides/proteins by gram-positive bacterium

Value of CORYNEX®

Applicable for Expression of Various Proteins

- Construct optimal production strain using a variety of breeding tools

- Especially highly suitable for VHH, antibody mimetics and long peptides

Simple Manufacturing Process

- High-titer and low-impurity due to secretory production

- Endotoxin free expression system

Highly-Efficient Total Production Process

- Conducting everything from strain development to fermentation/purification process development and analytical assay development at our own R&D site.

Suitable Platform for Drug Discovery

- Direct analysis of culture supernatants with low impurity content

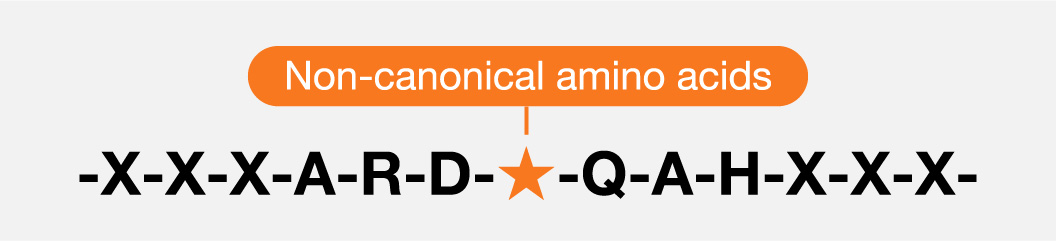

- Highly efficient introduction of non-canonical amino acids into desired sites as binding sites for other compounds

Technology

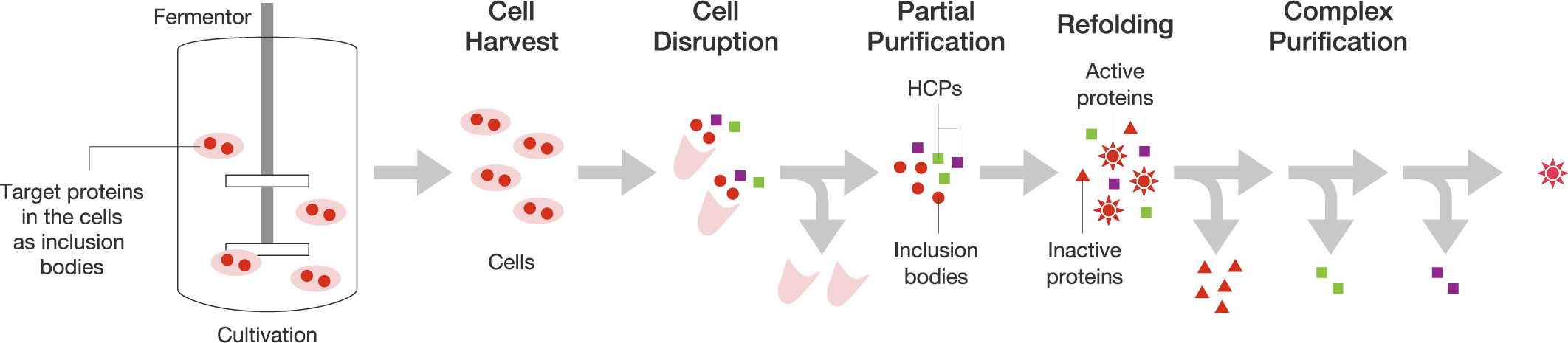

Manufacturing scheme and cost benefits with CORYNEX®

When manufacturing your target drug substance, CORYNEX® provides a simple process and affordable cost. The advantages of CORYNEX® technology include endotoxin-free, secretory production, low impurity and derivatives.

E.coil (traditonal system)

CORYNEX®(our system)

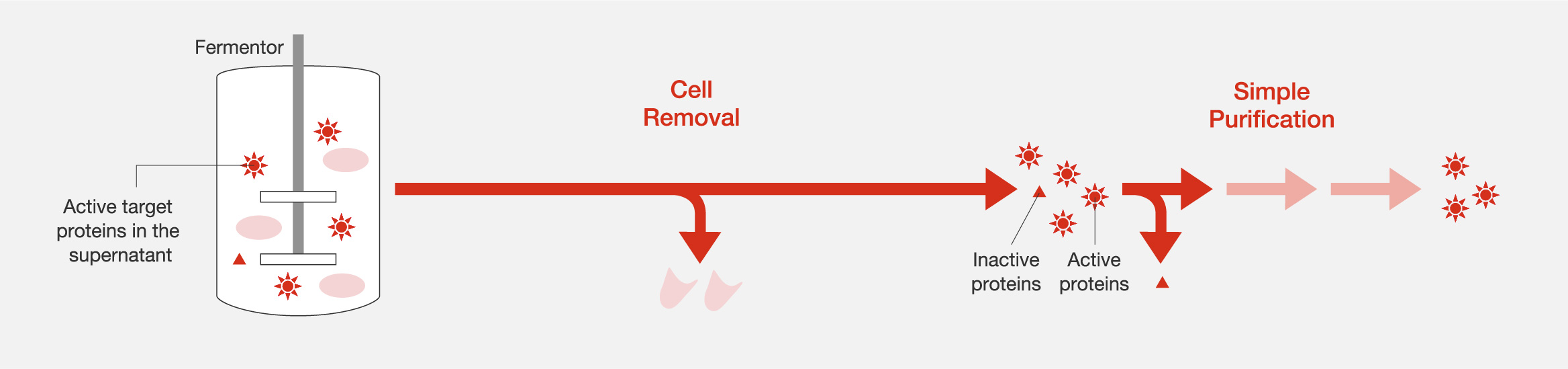

Usefulness of C. glutamicum strain as a protein/peptide producing host

About C. glutamicum

It is an FDA-certified producer and has excellent characteristics for low-cost pharmaceutical production compared to E.coil, such as the absence of endotoxin and the direct secretory expression of proteins in the culture medium.

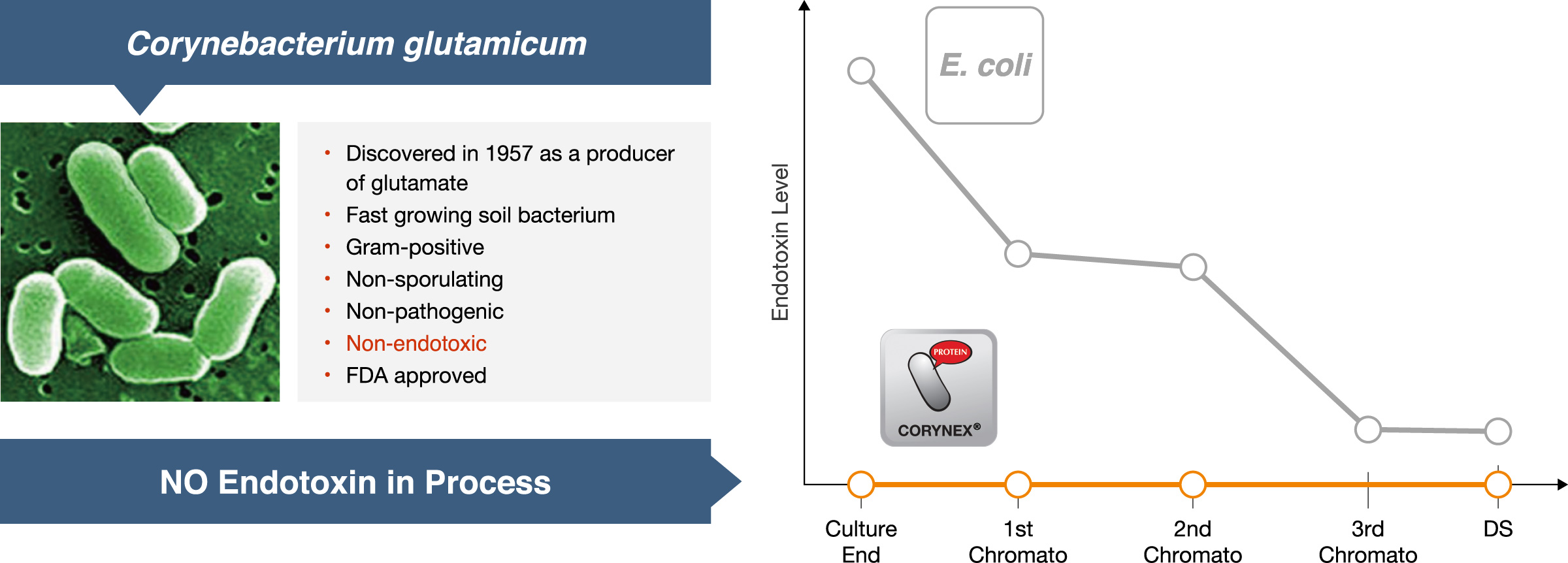

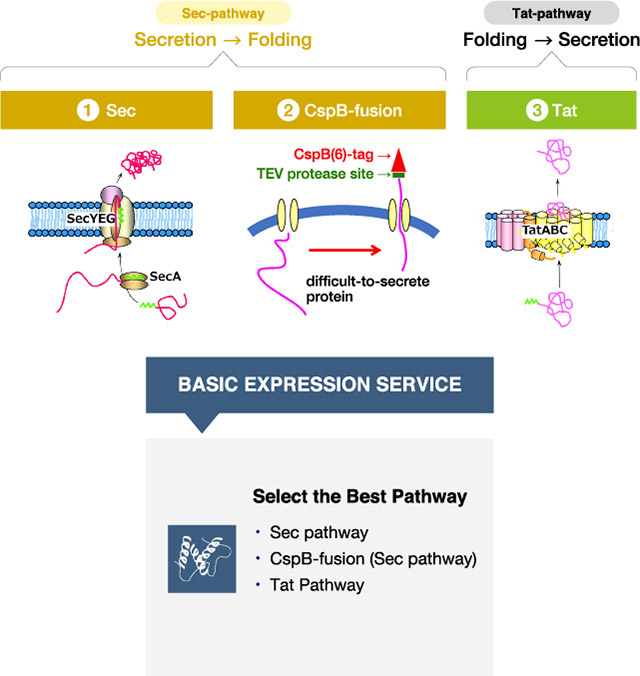

Diverse secretion systems and breeding tools

We examine three secretory pathways of the COYRNEX® system and utilize a variety of host cell/signal peptide libraries to construct optimal production strains.

- Three different secretion systems are available.

We select the best system that suits the characteristics of the target molecule. - 168 signal peptide libraries are available in the Sec system.

This is useful for expression enhancement. - CORYNEX® has host cell libraries.

We can select the most suitable host.

Example of Protein Expression

CORYNEX® can produce a wide range of peptides/proteins

CORYNEX® Success Examples

| Cultivation | Protein | Puropse | Secretion Pathway | Titer (g/L) |

|---|---|---|---|---|

| Fermenter | VHH | Biologics | Sec | ~11.0 |

| Fab | Biologics | Sec | ~1.5 | |

| Anticalin® | Biologics | Tat | ~4.0 | |

| Bacterial Antigen | Biologics | Tat | 3.0 | |

| Peptide | Biologics | CspB-fusion (Sec) | ~3.0 | |

| GLP-1 related | Biologics | Sec | ~3.0 | |

| Chemokine | Biologics | Sec | ~1.0 | |

| bFGF | Culture media | Tat | 2.0 | |

| IGF-1 | Culture media | Sec | 0.3 | |

| aFGF | Reagent | Tat | 3.0 | |

| Transglutaminase | Industrial enzyme | Tat | 8.0 | |

| Phytase | Industrial enzyme | Sec | 3.0 | |

| Protein A | Chromatography resin | Sec | 10.0 | |

| Test tube | DARPin® | Biologics | Sec | 1.0 |

| Adnectin | Biologics | Sec | 0.1 | |

| Protein G | Chromatography resin | Sec | 2.0 | |

| Protein L | Chromatography resin | Sec | 2.0 |

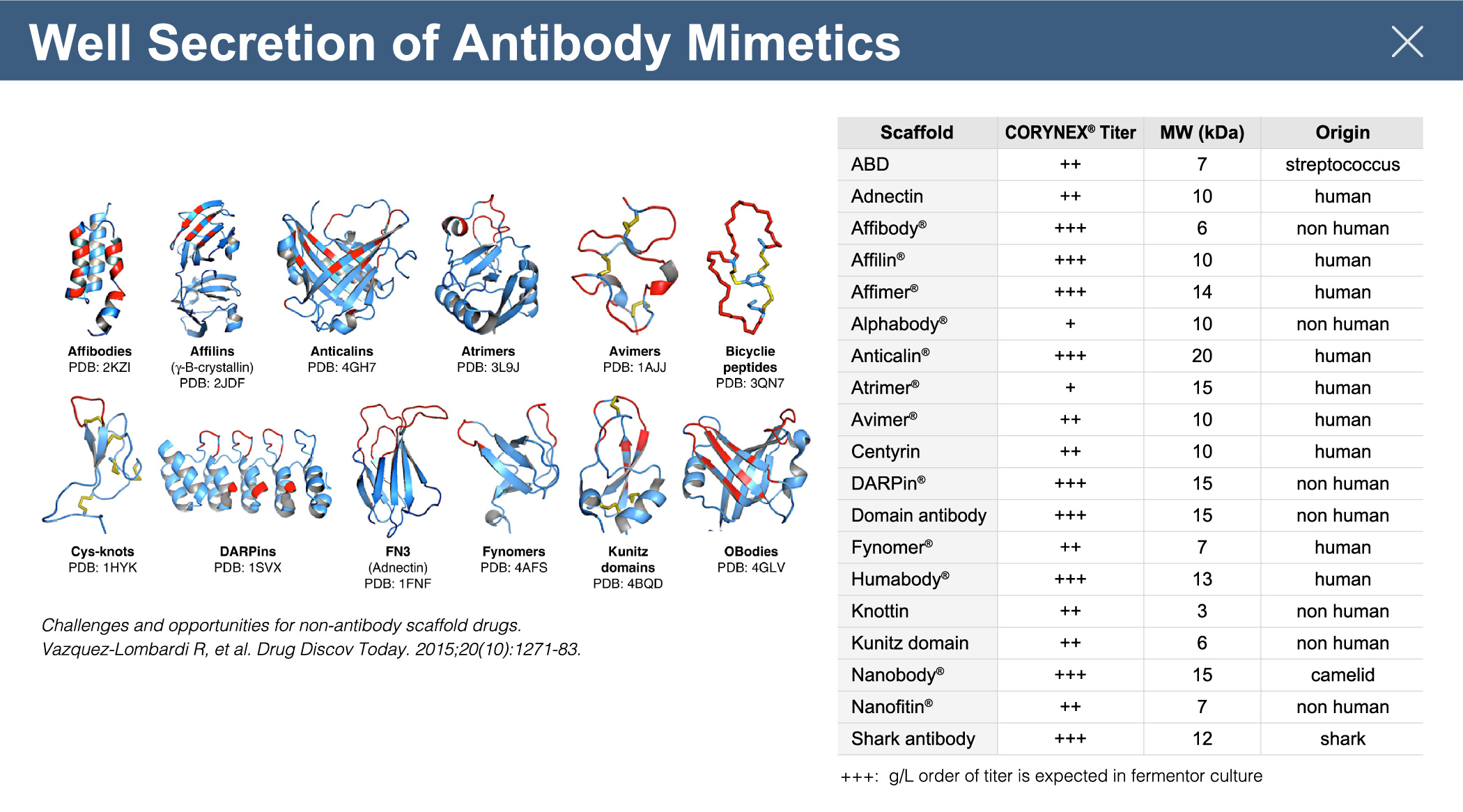

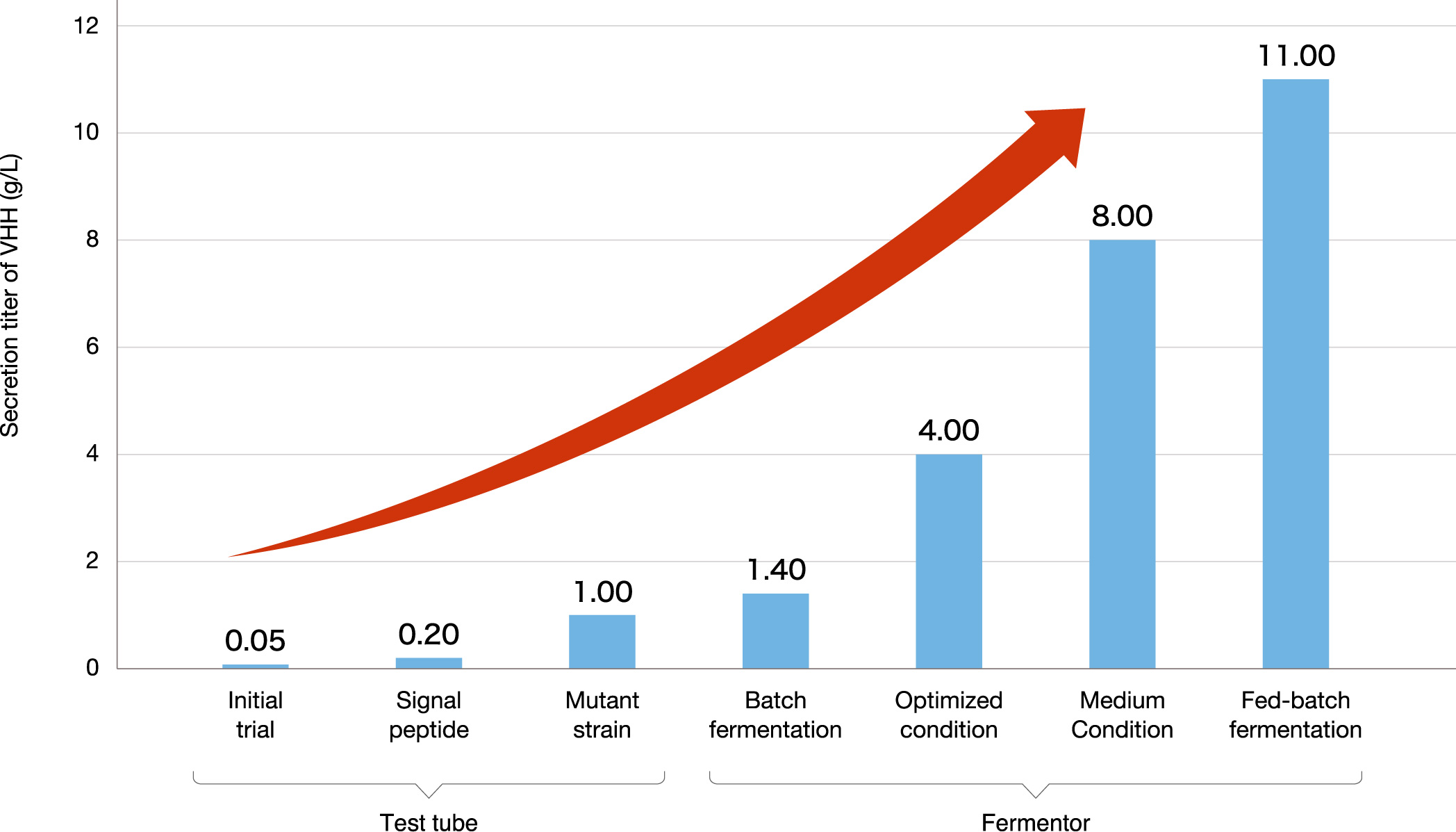

Especially suitable of production for VHH, antibody mimetics and long peptides

Improvement of VHH titer through strain improvement and development of culture process

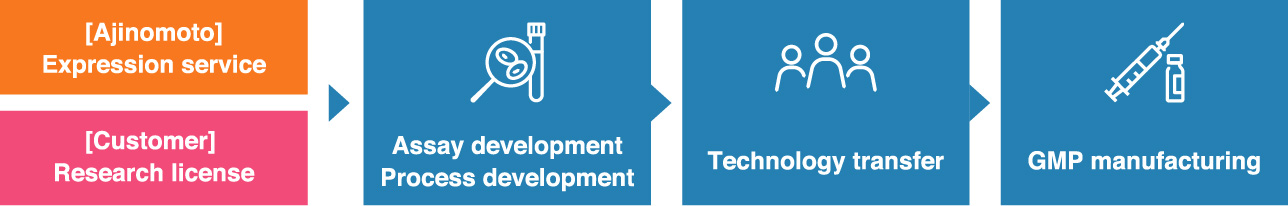

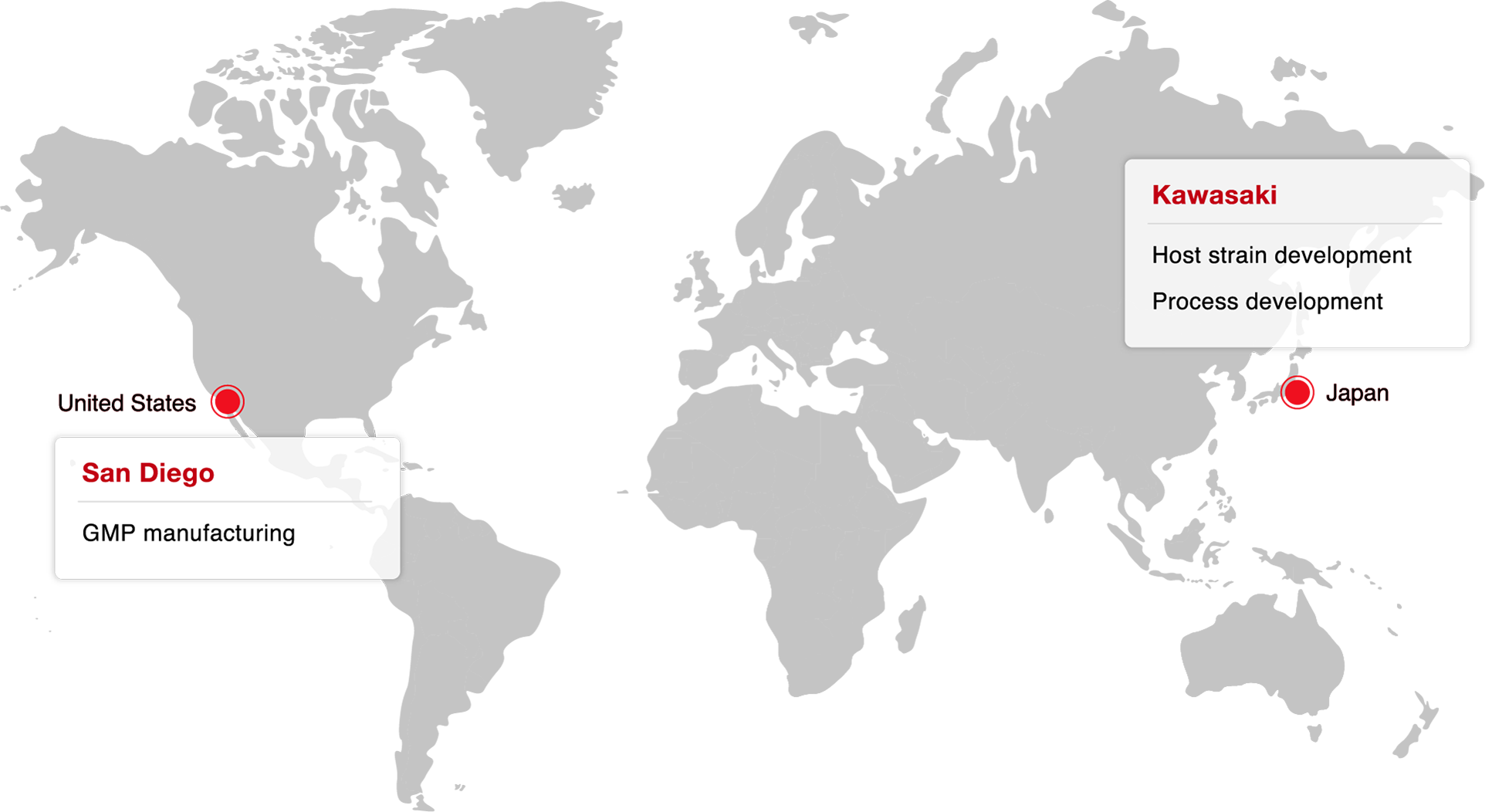

Global Service Offering

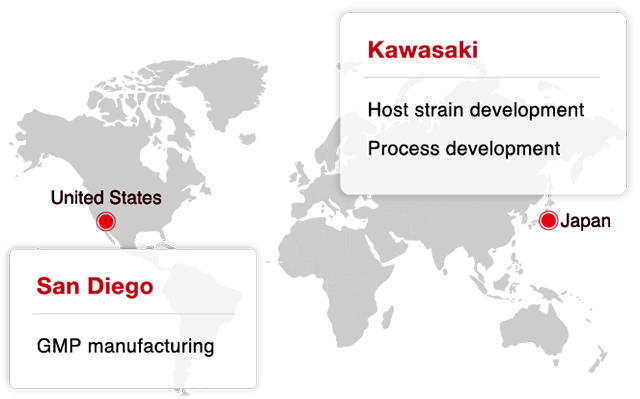

Ajinomoto Bio-Pharma Services provides the service for strain development and fundamental process development in Japan, then technology transfer to GMP manufacturing site in San Diego. We also have CMO partners across the world.

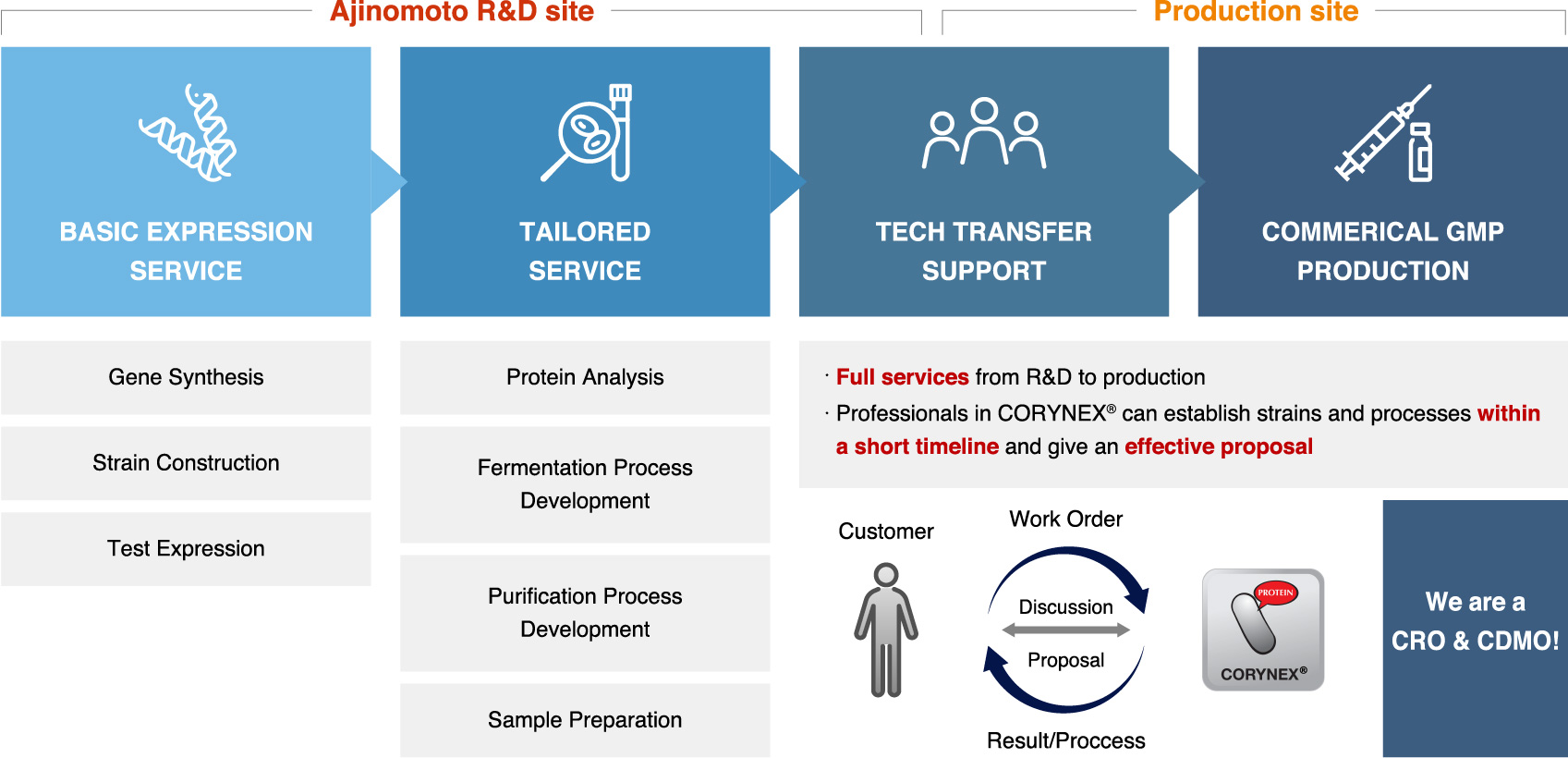

Service Flow

We have a strong R&D site in Japan. We can propose the most efficient total process by conducting everything from strain development to fermentation/purification process development and analytical assay development at our own site.

You can leave all development from test expression to GMP manufacturing to us.

The CORYNEX® team conducts your project step by step while collaborating with your project team.

Contact Us

For further information, please contact us using the link below and an Ajinomoto Bio-Pharma Services representative will contact you.