CONTINUOUS FLOW

CHEMISTRY

Chemical reactions to occur in a continuous, controlled, and scalable manner.

Value of CONTINUOUS FLOW CHEMISTRY

Easy scalability

- Continuous flow chemistry enables the seamless scaling of reaction volumes, making it ideal for both R&D and large-scale industrial production.

Fast and flexible production

- Continuous flow manufacturing provides enhanced control over reaction conditions, leading to higher yields, better product quality, shorter reaction times, and thus a shorter time-to-market for your product. Agility in production facilities is possible with the right portfolio of modular reactor skids.

Improved sustainability

- Continuous flow chemistry enables process intensification and thus potentially reduces waste, conserves resources and energy.

Increased safety

- Continuous flow reactions are performed in closed and highly controlled systems, reducing the risk of accidents and environmental contamination. It also allows to work safely with hazardous chemicals and even chemistries forbidden in batch.

Technology

What is CONTINUOUS FLOW CHEMISTRY

As an experienced CDMO in small molecule manufacturing for pharma and high value fine chemicals, we have made significant investments in continuous flow equipment over the past 10 years.

At our sites in Belgium, we have a wide range of reaction, extraction and distillation options for continuous flow manufacturing of liquids, slurries, and gas-liquids from lab to industrial scale.

CONTINUOUS FLOW REACTORS

1. Continuous Stirred Tank Reactor

(CSTR)

A CSTR is a mechanically stirred continuous reactor suitable for slow reactions and heterogeneous reactions. A cascade of CSTRs is commonly used in continuous flow chemistry for e.g. continuous crystallisations, continuous removal of volatiles, prolonged residence times.

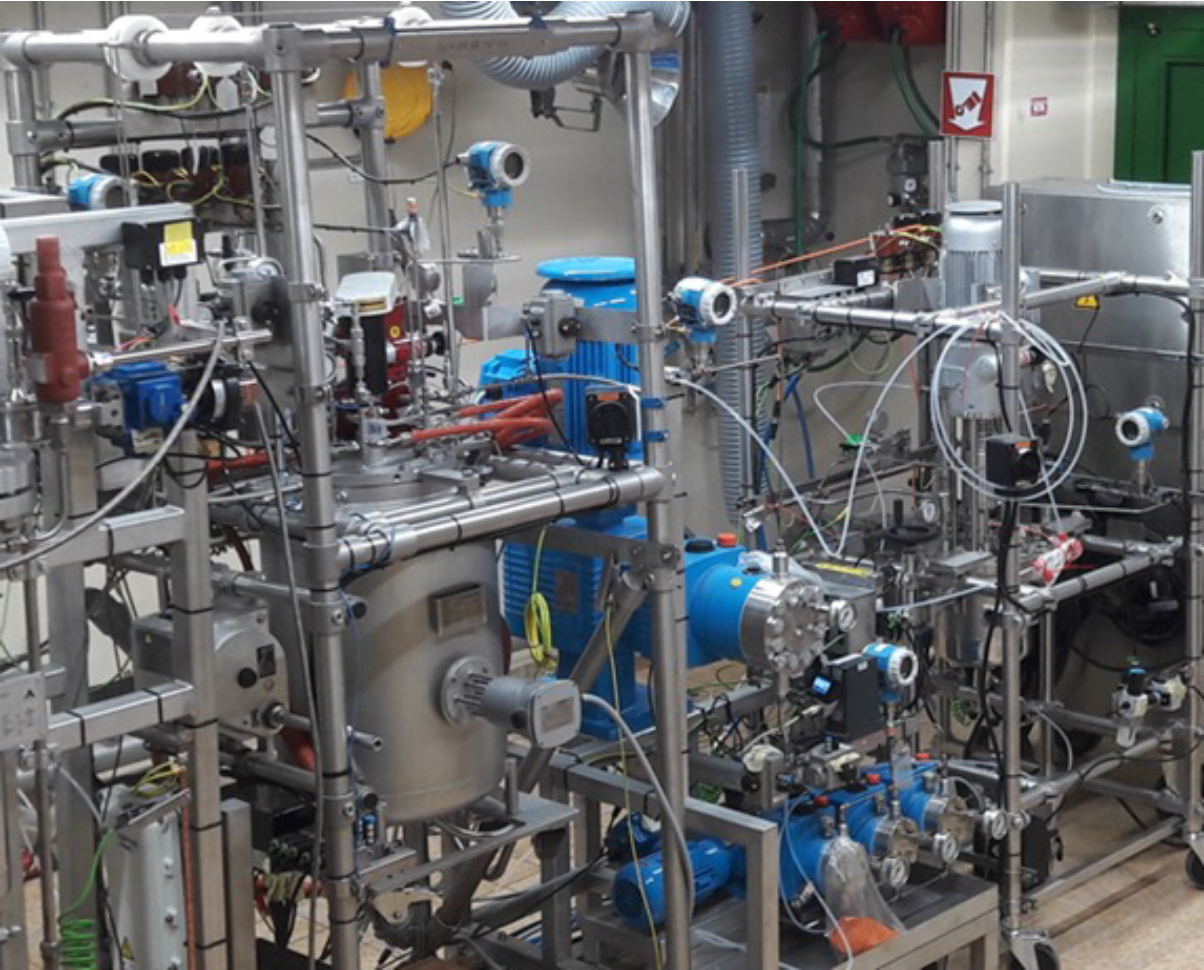

2. CØPE reactor

The in-house designed CØPE reactor is a tubular, high temperature, high pressure reactor that uses pulsatile flow for increased mixing. Our CØPE reactor is slurry compatible, making it suitable for reactions with solid catalyst, substrate, or additives.

3. Coil reactor

Our coil reactors are made up of a coiled tube in circulating thermal oil. It enables efficient mixing and precise temperature control and allow working at elevated pressure and/or long residence times.

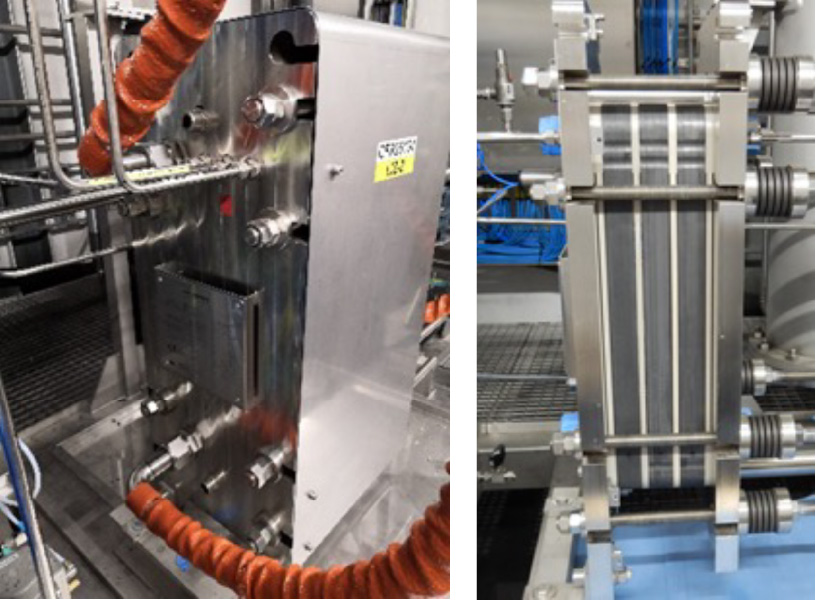

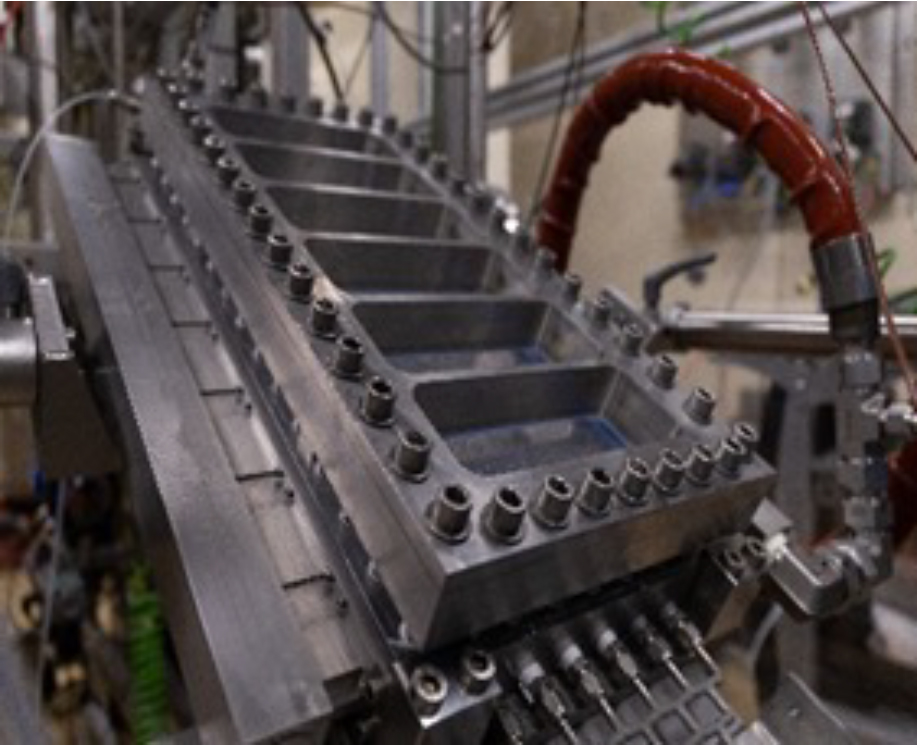

4. Silicium carbide plate reactor

Our plate reactor is very suitable for quick, exothermic and corrosive reactions.

5. HANU reactor

The HANU reactor is the first slurry-compatible photochemical plate reactor. Based on the COSTA® technology, it allows for linear scalability, low flow mixing, excellent temperature control, and a high degree customization.

This list of reactors is not exhaustive. We work with a wide range of reactors, which we continue to expand.

Each type of reactor offers its own set of advantages. Depending on your product requirements, we choose the most suitable reactor.

CONTINUOUS FLOW EXTRACTION TECHNOLOGIES

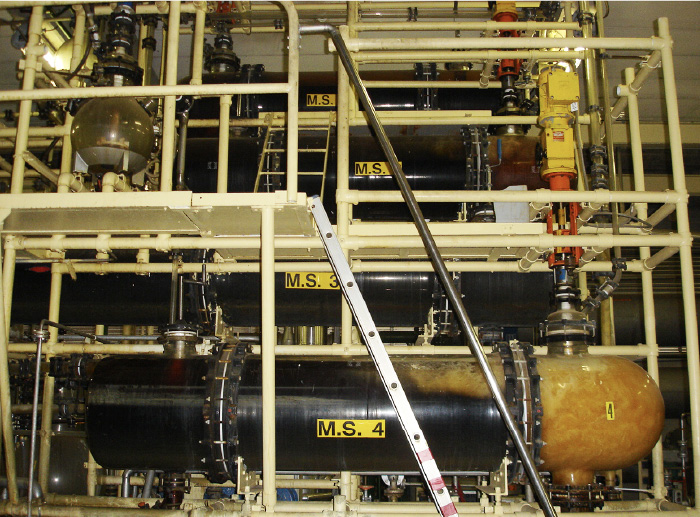

1. Mixer-Settler extraction

Mixer-settler extractions involve mixing two immiscible liquids to form a dispersion, followed by gravitational settling to separate the two phases. Multiple stages in co-current or counter-current mode are possible, reducing the solvent usage and increasing the processing rates.

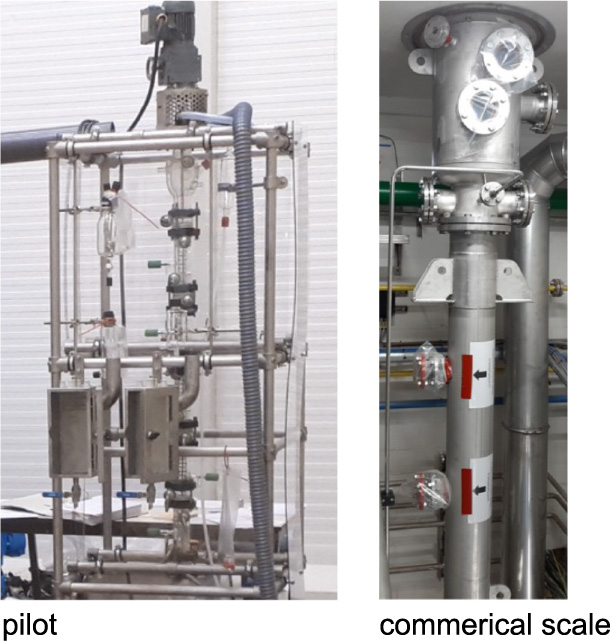

2. Agitated column extraction

Counter-current extractions in agitated columns allow many extraction stages in one device. They are suited for efficient continuous extraction of target compounds with significant reduced solvent or water consumption e.g. removal of toxic side products to ppm levels.

3. Centrifugal extraction

For centrifugal extractions we use a high-speed centrifuge to mix and separate two immiscible liquids even with limited difference in densities. A cascade of centrifugal contactors are used frequently in co-current or counter-current mode allowing fast processing time and reduced solvent consumption.

4. Membrane assisted phase

separations

After intensive mixing of two immiscible liquids the phase separation can be done with the aid of porous membranes. The difference in wetting of the membranes and a small pressure difference over the membrane (e.g. the Zaiput SEP-200) allows even the separation of emulsions or liquids without density differences from the lab scale to commercial scale.

This list of extraction technologies is not exhaustive. We work with a wide range of extraction techniques, which we continue to expand.

Depending on your product requirements and the rest of the continuous flow process, we choose the most suitable extraction technique.

PROCESS ANALYTICAL TECHNOLOGY (PAT)

We use inline and online monitoring tools to monitor the continuous flow reactions.

They allow us to optimize the process, enhance safety and control the quality of your API’s.

- • NIR gas flow cell

- • NIR liquid flow cell

- • RAMAN liquid flow cell

- • UV liquid flow cell

- • Particle video imaging flow cel

This list of process analytical technologies is not exhaustive. We work with a wide range of PAT, which we continue to expand.

Depending on your product requirements and the rest of the continuous flow process, we choose the most suitable solution.

Track Record

Complex and innovative chemistries are at the heart of Aji Bio-Pharma Services. As science-based company we do have more than 10 years of experience in continuous flow from lab to commercial scale, producing pharmaceuticals and high value fine chemicals.

Global Service Offering

At our two manufacturing facilities in Belgium, we are able to scale your continuous flow process both GMP as well as non-GMP to an industrial scale.

Contact Us

For further information, please contact us using the link below and an Ajinomoto Bio-Pharma Services representative will contact you.